Fish meal & oil processing

Short Description:

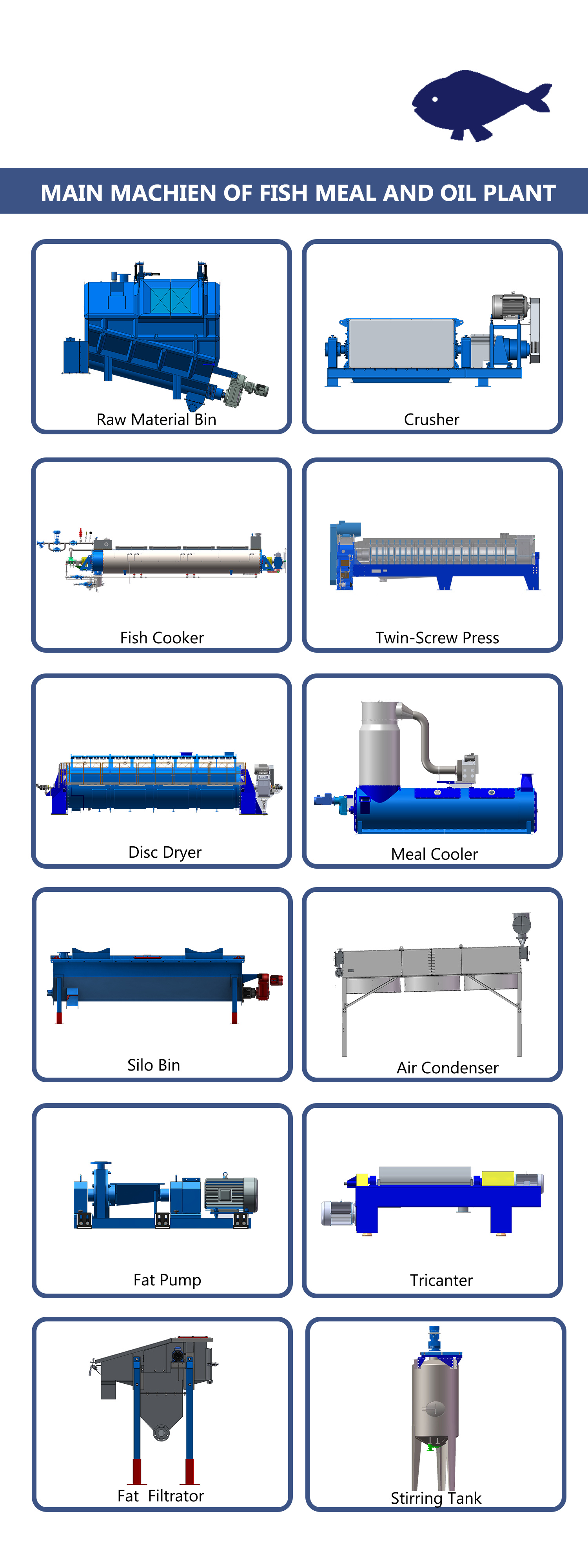

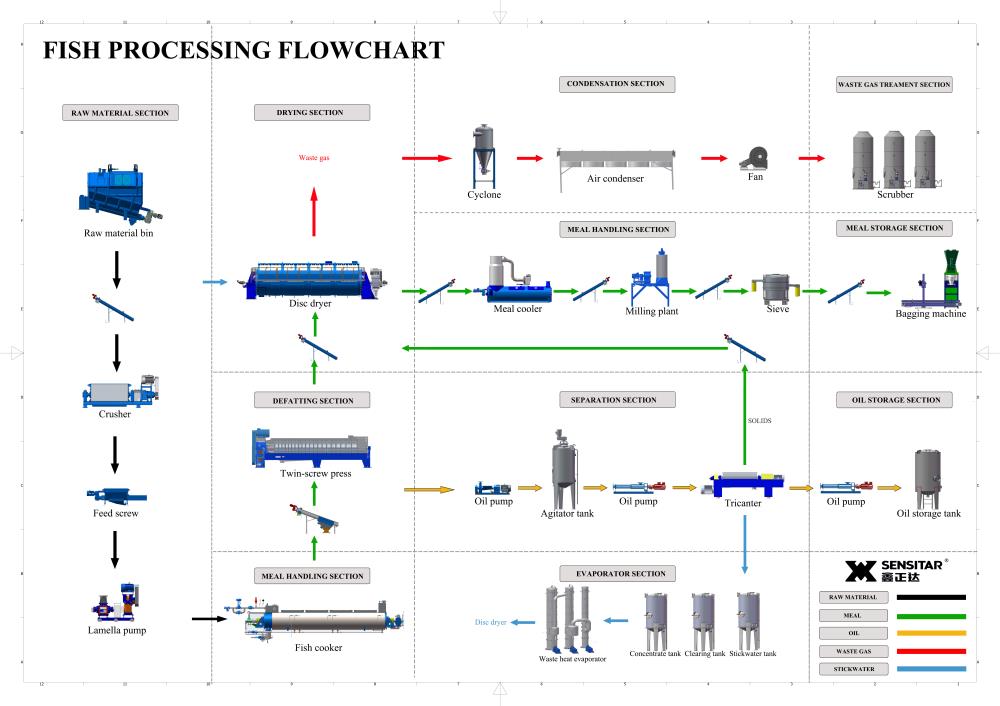

Sensitar Fish meal&oil Processing Systems are available as complete, turnkey installations including cooker, solids/liquids separation, evaporation and drying equipment, and control systems specifically engineered for fish meal process requirements. Individual system components are also available to improve the performance of existing installations. The Sensitar fish cookers are applied in processes where high yield from raw material of variable quality and composition is required.Fish me...

Sensitar Fish meal&oil Processing Systems are available as complete, turnkey installations including cooker, solids/liquids separation, evaporation and drying equipment, and control systems specifically engineered for fish meal process requirements. Individual system components are also available to improve the performance of existing installations.

The Sensitar fish cookers are applied in processes where high yield from raw material of variable quality and composition is required.Fish meal and turkey offal are examples of such processes.

The Sensitar disc dryers are the ideal solution for removing as much water as possible, as gently as possible, from coarse fish, animal or poultry by-products with low fat content.

The Sensitar twin-screw press is an ideal part of the wet rendering process for extracting liquid from cooked fish or meat.

The Sensitar Decanter is three-phase separation, which can achieve good solid-liquid separation effect.

The Sensitar Air-cooled condensers use flowing air to condense steam from cooking or drying fish or meat byproducts to help ensure effective odor reduction.

The Sensitar Cooler uses the way of quick water-flow to cool the powder and small particles of the material, while cooling the material, the material according to different requirements of different particles

Sensitar also supplies compact fish meal plants with all machines mounted as one unit. This includes cooker, strainer, twin screw press and dryer, Separately, an oil recovery system and an evaporator can be installed.Our compact plants are pre-assembled and ready to install either on board floating factories or ashore for treatment of by-products from fish processing.

Engineering and Manufacturing

Sensitar engineering experts, with years of experience in the fish meal processing field.Sensitar fish meal plants and equipment offer unsurpassed capability to provide efficient, profitable and sustainable solutions.

Your system begins with thorough consultations with our staff of experienced applications engineers, who work with you to develop cost effective ways to maximize your fish meal processing operation. Our product development and engineering team translate your needs into specific plans for everything from turnkey rendering plants to individual pieces of equipment designed to improve your current system.