factory Outlets for High Output Manufacturing Pet Dry Dog Food Production Line Extruder Floating Fish Feed Pellet Making Processing Machine

Short Description:

As a way to finest meet up with client’s wants, all of our operations are strictly performed in line with our motto “High Quality, Aggressive Price, Fast Service” for factory Outlets for High Output Manufacturing Pet Dry Dog Food Production Line Extruder Floating Fish Feed Pellet Making Processing Machine, Living by quality, development by credit is our eternal pursuit, We firmly believe that after your visit we will become long-term partners. As a way to finest meet up with...

As a way to finest meet up with client’s wants, all of our operations are strictly performed in line with our motto “High Quality, Aggressive Price, Fast Service” for factory Outlets for High Output Manufacturing Pet Dry Dog Food Production Line Extruder Floating Fish Feed Pellet Making Processing Machine, Living by quality, development by credit is our eternal pursuit, We firmly believe that after your visit we will become long-term partners.

As a way to finest meet up with client’s wants, all of our operations are strictly performed in line with our motto “High Quality, Aggressive Price, Fast Service” for China Dog Food Production Line and Dog Food Production Machine, To get more information about us as well as see all our products, please visit our website. To get more information please feel free to let us know. Thank you very much and wish your business always be great!

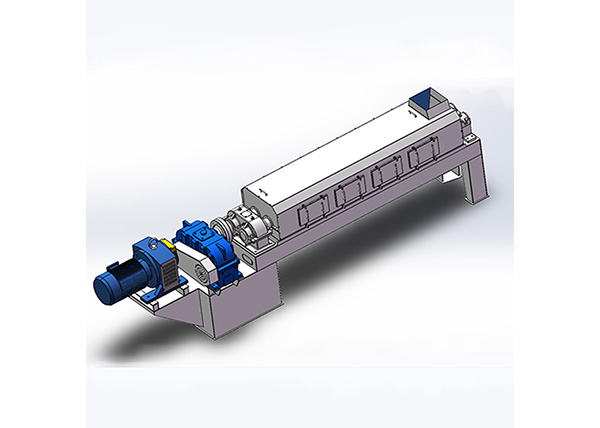

For pressing liquids from cooked fish or meat in a wet rendering process. The twin screw press ensures eficient mechanical dewatering and reduction of the oilfat content, which improves processing and increases the energy saving potential. The twin screw press attains a condition of high compression resulting ina low moisture and oilfat content in the press cake.

The press consists of two interlocking screws enclosed by a strainer shell and surrounded by a cover. The flights’ geometry can be cylindrical or biconical depending on the performance required and the type of material being processed. The screws rotate in opposite directions, preventing the material from rotating with the screws.

The strainer cage consists of perforated stainless steel plates surrounded by mild steel supporting plates, which are supported by heavy steel bridges.The strainer plate holes vary in size of the press from inlet to the outlet from 5 to 1. The twin screwpress can be dlivered as a conical or a cyindrica press One of the advantages of the conical type is that the flights of one screwreaches almostinto the core of the other screw.The result is minimum slip in the press and a more uniform press cake.

Twin-screw presses are often used to extract liquid from cooked fish or meat as part of low-temperature wet rendering processes.

They are also ideal as the first stage in mechanical dewatering processes, before the material enters a centrifugal decanter centrifuge.

They can also be used in high-capacity feather plants.

| Type | Capacity (t/h) |

Dimension(mm) | Weight (mt) |

Power (kW) |

||

| Length (L) | Width (W) | Height (H) | ||||

| TP 24 | 2.5 | 4400 | 1250 | 1030 | 3 | 7.5-11 |

| TP 35 | 5 | 5460 | 1800 | 1300 | 7 | 11-18.5 |

| MS 41 | 13 | 4600 | 2000 | 1500 | 9.5 | 22-37 |

| MS 49 | 18 | 5700 | 2400 | 1950 | 15.5 | 30-55 |

| MS 56 | 25 | 6700 | 2500 | 1870 | 23 | 45-75 |

| MS 64 | 40 | 7400 | 2800 | 2100 | 31 | 90-110 |

| RS64 | 50 | 8350 | 2800 | 2100 | 34 | 110-132 |

| XS88F | 60 | 8400 | 2850 | 2165 | 46 | 95-132 |